Explore our legacy of innovation

Pioneering analog

sound since 1948

Crafting perfection in Moving Coil cartridges

Ortofon's sonic evolution

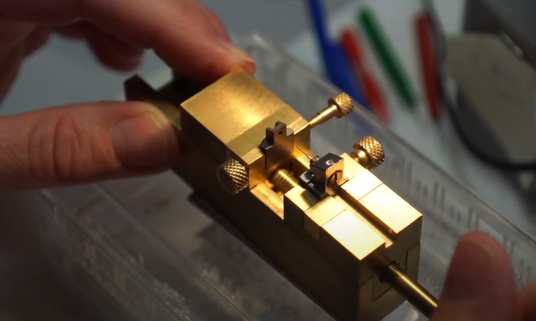

Precision insertion of rocker spring

Assembly expertise

Moving Coil Cartridges

Custom Winding Techniques

Meticulous Pretension

Pole cylinder assembly